How To Install Components For A Universal Coupling?

Oct 15, 2021

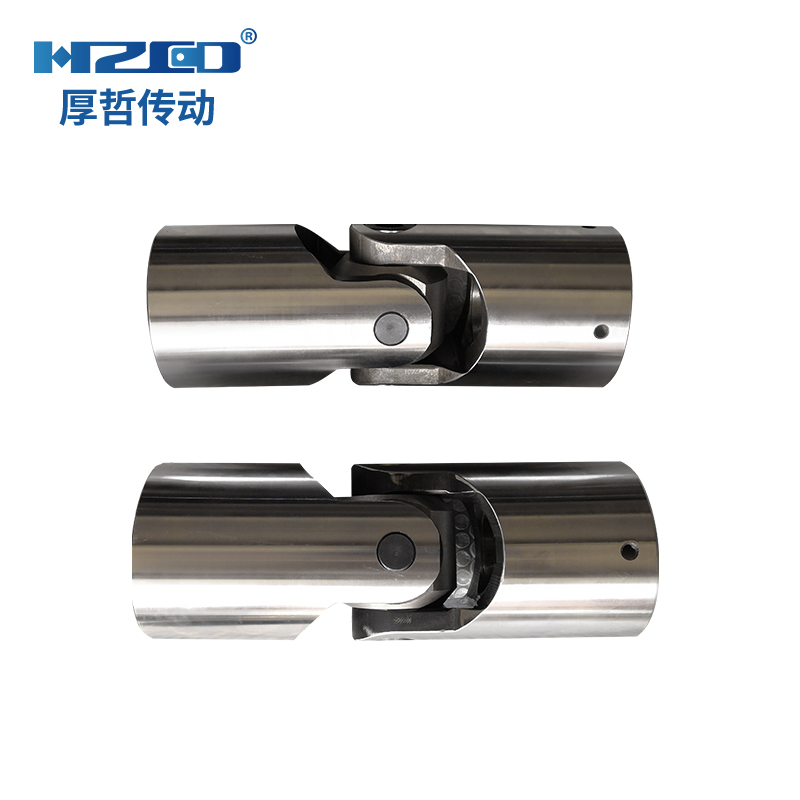

Intermediate shaft of the universal joint is generally divided into left and right parts to adapt to different working conditions.If spline connection, the mutual position of the fork surfaces at both ends can be adjusted by changing the assembly relationship of the splines.The reasonable universal joint transmission design can reliably transmit power, suppress the vibration generated in the transmission, and ensure that the two shafts rotate at the same speed and transmit the same torque as much as possible.Therefore, it is necessary to perform theoretical modeling and simulation analysis on the dynamic characteristics of universal joints. The universal joint is composed of two single joints and an intermediate shaft, which can realize the connection of two axes that are intersecting, parallel or spatially staggered, and realize the movement and power transmission between the two shaft couplings.It plays an extremely important role in the development of mechanical engineering and the automotive industry.As the angular velocity of single joint the driven shaft changes periodically, additional dynamic loads will be generated in the transmission, causing the shaft to vibrate.If use universal joints can eliminate this disadvantage. Should be carefully check installation of pneumatic clutches, main motors, and universal joint reduction gears to remove abrasions and burrs generated during transportation.Install only after cleaning.Should according to the instructions provided by the manufacturer to install the main motor. Not only the coaxiality and inclination of the main motor universal transmission shaft should same as the transmission shaft of small gear device,that is 1/1000, but also the inclination direction of the ball wear. If there is an error in the inclination and height, you can add a spacer under the motor base to adjust it.If there is an error in the parallelism, the rotor bearing position of the movable motor should be carefully adjusted to achieve high accuracy.When installing a low-speed device, after installing a planetary cycloid reducer with a motor, need sure that device can easily move the claw clutch without jamming, disengaging, or tilting. Link point and disconnection between the limit switch and the stopper are reliable.The surface of the axially moving semi-universal coupling, the link surface between the slider of lever device and the matching groove should be coated with grease.The parallelism between the ball mill pinion shaft and the cylindrical shaft must not exceed 0.15 / 1000.When installing the universal joint gear cover, check whether the gear cover has been deformed during long-distance transportation, whether the oil-resistant paint has fallen off,if its fallen off ,should paint again. When installing the gear cover, pay attention to inspection and correction to ensure that the gear does not collide when its running. When the ring rotates, the felt ring should closely fit the large gear, not allowed gap.

Read More